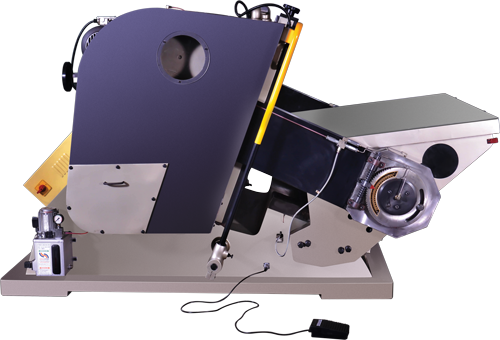

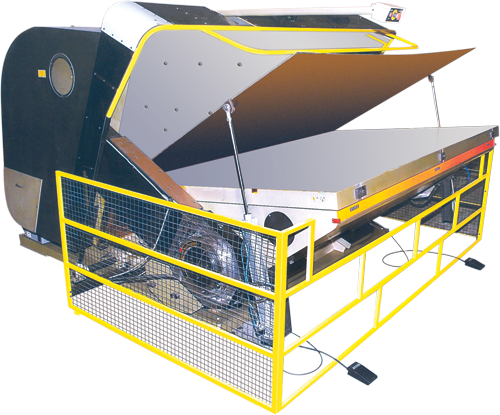

The Platen is one of the popular creations, designed for Die Cutting, Scoring & Creasing of various articles like Paper, Linoleum, Cardboard, Corrugated Board, Wonder Board, Fibre Board, Cork, Leather, Plastic, Vinyl, PVC material etc. The Platen is patronized for more than one reason. It is compact in size, and hence, requires minimum floor space. It is designed to take minimum ‘MAKE-READY’ time. It provides the most optimum hourly production. It is more presentable than any of the me‑too’s on offer.

EVEREST is the name & style, under which, all products are designed & made in the house of SOND, leave premises for domestic utility or use across the seven Seas. Under the brand name of ‘EVEREST’, SOND has been manufacturing sturdy machines since 1965 for superb precision, unsurpassed reliability & virtually in destructible quality.

The Main Body of the Platen is quite sturdy, ensuring smooth operations under trying condition. The Main Frame, as well as the Platen are made of special highly tensile Cast Iron, and can, therefore, resist even the slides of deformation under the heaviest of strains. In fact, for customers, that have ‘Half‑Cut’ job, it is necessary the maximum machine rigidity. EVEREST body structure is carefully designed to withstand the heaviest loads to provide unsurpassed cutting precision and many years of reliable service. Enough ‘Goose Necks’ / thick support bars are inside of the platen (moving & fixed) in order to give minimum deflection under heaviest load. Further, each Platen is machined & finished to obtain perfectly level surfaces.

A lot of attention has been given for ‘Connecting Arms’. High tensile steel is used and their dimensions are carefully calculated to bear the maximum material stress.

The main Gears Shaft & Connecting Arms are mounted on Phosphorus Bronze Bushes. Ball / Roller Bearing Mounted Crank Shaft drives the Platen through a pair of high‑speed Double Helical Gears (for increased strength) and two pairs of reduction Spiral Gears being lubricated by Grease / Oil.

Our constant strives for better machines & enormous experience gained over the years in the field of quality Die Cutting & Creasing Platen. We at SOND use quality material suitable for every part of the machine, such as - Shafts, Cam & Roller, Sliding / Guiding Plates for the Moving Platen, Connecting Arms, Phosphorus Bronze Bushes, Ball / Roller Bearing etc. The main Gears Shaft Connecting Arms are mounted on Phosphorus Bronze Bushes. The Reduction Gear is made of Hardened Quality Alloy Steel / Cast Nylon.

A lot of attention is being given to the minutest of detail. For example, a quick adjustment of impression is made through two Eccentric Bushes and the degree of adjustment can be easily noted on a Calibrated Scale. The device allows and infinities impression control down to a few microns. This feature considerably EXTENDS DIE LIFE, substantially reduces make‑ready time and simplifies ‘Kiss cuts’. Operators can adjust cutting pressure with unprecedented precision. An Impression Counter keeps an accurate count of the impressions made by the Machine.

There are other special Devices like the Dwell Timing Devices, which can be set to give a variable period from a least count of 0.5 sec. to 10 sec. During the period, the Moving Block remains stationary in the open position before automatically resuming motion at the end of the set dwell period. The feature is particularly useful when feeding requires a fine register or when large or difficult Sheets are being fed which would otherwise have to be run using the Single Impression procedure. This Device can provide more than double the output when compared with single impression working. It is also of great assistance in training of Operators.

All moving parts of ‘EVEREST’ Machines are protected by internationally desirable & approved Safety Guards. In addition, a specially designed Guard protects the operator from the Moving block. Should any object comes between the Moving Block & the Guard, a slight backward movement of the Guard will occur stopping the Moving Block immediately, switching‑off the starting mechanism. Until & unless the Guard is relocated, the Machine remains at a standstill & unaffected by any attempt to actuate it through the starting mechanism. The sensitive ‘Safety Photo Sensor’ & ‘Foot Brake’ come standard in EVEREST. These Safety Devices assure that users are kept out of harms’ way.

Very few Engineering Houses have such an elaborate list of useful mother machines / accessories as SOND has. This is also a direct result of our strong belief in our two pronged thinking Utility & Quality, in every sense of the word in every area it can be applied.

The following is a list of Standard Accessories:-

Single Dwell Facility, Wrap Around Safety Device, Safety Photo Sensors/Foot Brake, Automatic Sheet-Counter, Two Normal Chases with First Four Models, One Adjustable Chase with remaining four Machines, Standard Make-Ready Plate, Electro-Magnetic Clutch / Brake, Automatic Lubrication System, A complete set of Service-Tools.

An Imported Hardened & Ground-True “Specific” Make-Ready Plate, Steel Chase with Adjustable Frame Bars, Variable Speed Control, Air Clutch / Brake, Pneumatic Lifter for Make-Ready Plate, or any other special accessories on request. All at extra cost.